- Laser-cut saw plate made from saw blade specific alloy and flattened to ensure that the blade runs straight and true.

- Superior grade Tungsten Carbide tips specifically suited for your application including sub micron grain C-4 when appropriate for extended edge life. Large carbide tips mean more sharpening points per blade.

- Robotic CNC controlled brazing and grinding machinery produce consistent and precise tolerances.

- Thousands of blades in stock as well as custom-made blades.

- Quality blades provide for greater productivity without downtime.

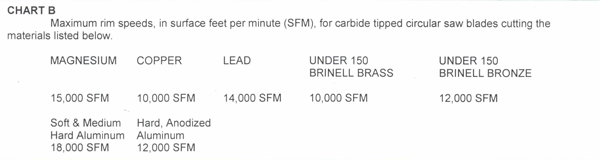

Non-Ferrous blades are furnished with a TCG or LRTCG grind and positive 5 to negative 5 degrees of hook, depending on the application. Heavier plates help support the rigors of cutting non-ferrous metals. Always use mechanical clamping and lubricant spray when cutting non-ferrous metal. As a general rule, use more teeth for thin material and fewer teeth for thicker material. Contact our technical sales team to assist in choosing the correct blade for your job. Non-Ferrous blades are a good choice for cutting plastic. Choose more teeth to get clean cuts on plastic.